how do you measure the thickness of sheet metal|10 gauge sheet metal thickness : distribution If you have to measure a specific, single sheet of paper, use a digital caliper instead for the most accurate result. . on one end. If you’re using a digital model, it will also have a display situated on the ruler portion. Look for a metal wheel attached to the bottom edge of the scale. . then do some additional math to figure out the .

OnlyFans is the social platform revolutionizing creator and fan connections. The site is inclusive of artists and content creators from all genres and allows them to monetize their content while developing authentic relationships with their fanbase. Just a moment. We'll try your destination again in 15 seconds .

{plog:ftitle_list}

23 de fev. de 2024 · Find the best Ashe build guides for S14 Patch 14.3, including runes, items, abilities, skins and more. Learn from top rated guides, watch video tutorials and .

One of the most accurate ways to measure the thickness of thin sheet metal is by using an ultrasonic thickness gauge. This method involves sending high-frequency sound .

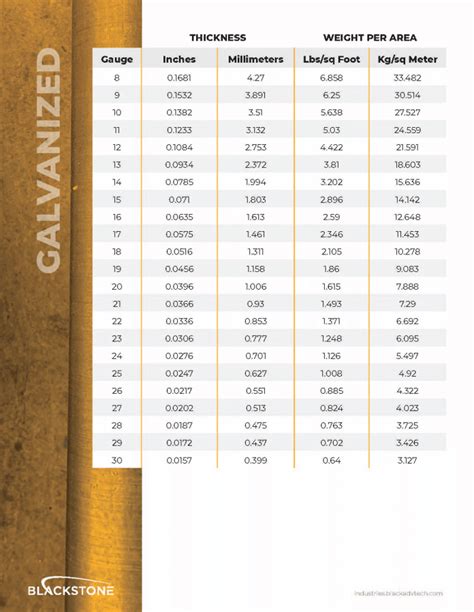

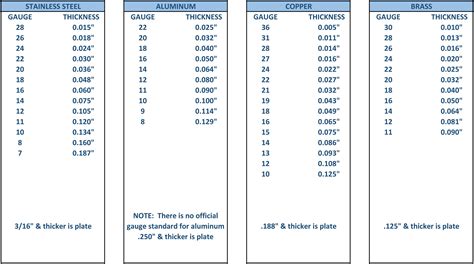

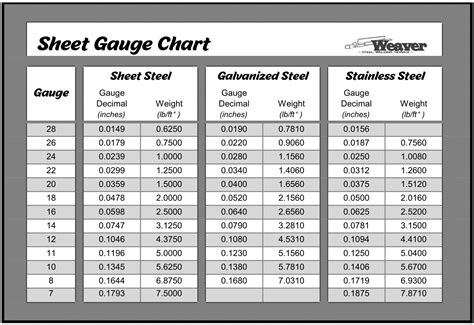

Sheet metal thickness is measured in gauges; the higher the number, the thinner the sheet metal. The most commonly-used sheet metal sizes range from 26 gauge (thinner) to 7 gauge (thicker). A sheet metal . In today’s metal industry, gauge and inch measurements are both used to describe thickness. Below, we’ve outlined the distinctions between each method. Measuring Sheet Metal Using the Gauge Measurement System. When purchasing sheet metal, the thickness is typically measured via the gauge system. Unlike other measurements, gauges . Step 2: Measure Expanded Metal Thickness. Using a caliper, measure the thickness of the expanded metal sheet or panel. This will help you determine the gauge or wire diameter of the material. Expanded metal is .Screw gauge is an instrument used to accurately measure the thickness of a sheet of metal. It comprises a U-shaped frame fitted to a screwed spindle which is attached to a thimble. A scale graduated in mm is engraved parallel to the axis of the thimble. This is known as the pitch scale.

If you have to measure a specific, single sheet of paper, use a digital caliper instead for the most accurate result. . on one end. If you’re using a digital model, it will also have a display situated on the ruler portion. Look for a metal wheel attached to the bottom edge of the scale. . then do some additional math to figure out the . Improve your sheet metal bending operations and achieve precise results every time. . Measure the thickness 𝑇 of the aluminum plate. Apply the formula 𝐿=𝐿1+𝐿2−1.6𝑇. This calculation will give you the flat pattern length required before bending, ensuring that the final bent part has the correct dimensions. .

A variety of electronic instruments are available for measuring after cure powder coating thickness on metal parts. They use a magnetic principle when measuring on steel and an eddy-current principle on aluminum. Measurement results are displayed on an easy-to-read liquid crystal display (LCD). Typical tolerance is between ±1% and ±3%. The thicker the base metal, the larger the welding rod diameter and the amperage. The larger the rod in relation to the thickness of the metal will cause a higher deposition rate and faster welding. If you select a welding rod with the same diameter as the metal thickness, this can cause too much heat and result in warping and blow-through.

To measure the thickness of an expanded metal sheet using a gauge, place the sheet onto a flat surface with one edge resting against a flat edge, ensuring that the sheet is perpendicular to the edge. Slide the gauge’s pointer along the sheet’s surface, recording the measurement displayed on the gauge.

Choosing the right sheet metal gauge and thickness is essential to any metal fabrication project. . Galvanized steel sheet metal measuring 30 gauges equals 0.0157 inch, but the same gauge standard steel sheet metal measures 0.0120 inch and 30-gauge stainless steel measures 0.0125 inch. It should be noted that aluminum is usually classified by .Gauge: The thickness of the original base metal before it is expanded. Finished Thickness / Strand Thickness: The thickness of the expanded metal. Strand Width: The size of the solid metal portions of the grating. Bonds / Bond Width: The intersection of the stands. The bond width it typically double the width of the strand. It might be obvious to some, but also less obvious to others. More and more these days fabricators take delivery of their sheet metal, do what needs to be done, then simply ship it onwards, knowing already that its dimensions, and thickness are correct, all is well and never even needing a sheet metal gauge tool.

Why do a sheet metal bending calculation? Because sometimes you will need to work around a bend, and you may need to know sheet metal bend allowance. . If you multiply the material thickness by the K-factor (0.446), you get the location of the relocated neutral axis: for example, 0.062 × 0.446 = 0.027 in. This means that the neutral axis . A gauge is a unit of measurement used to measure the thickness of a flat sheet of metal. The gauge chart—a handy chart for converting gauges to other units of measurement—generally runs from 0 to 38, though it varies depending on the kind of metal used. The higher the number, the thinner the metal, and vice versa. The Gauge Chart For sheet metal projects, not only do you need to pick the right material option, but you also need to pick the right sheet metal thickness, or “gauge”. . When it comes to measuring sheet metal thickness, there are .How do you measure pipe thickness? If you’re looking to measure the thickness of a pipe, an ultrasonic thickness gauge should be used. A handheld thickness gauge, such as the 27MG gauge, will offer accurate measurements .

Keeping a gauge conversion chart nearby is an easy way to determine the actual thickness of a sheet of metal in inches or millimeters. For example, a 14 gauge stainless steel is .07812 inches thick. . You can use . Ensuring you select the right sheet metal gauge, or thickness, is crucial for the integrity, durability, and efficiency of the final product. The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed decisions for your specific applications. While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up to 13 in. or even more. Likewise, plate steel varies in strengths from mild varieties to some very high-strength materials such as Hardox ®. When it comes to very thick or high-tensile-strength material .A calliper is a hand tool designed specifically to measure the distance between two points. Fit the two tips of the calliper around the metal you need and you can accurately measure the thickness. This is a useful method when replacing an existing piece when you know the new sheet of aluminum will have to be identical to what it’s replacing.

Sheet metal gauge refers to a standardized method used to measure and categorize the thickness of sheet metal. This system, . gauging follows its own set of rules. To find out the actual thickness of sheet metal, you can refer to a gauge conversion chart. This chart helps translate gauge numbers, such as 18 gauge, into familiar measurements .When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the

Now that you already know what a sheet metal gauge is, you should learn how to measure sheet metal thickness. You can measure the sheet metals using regular tape or a gauge wheel. With a sheet metal gauge chart (is shown in next part), you can convert the gauge size to mm or inch. Solution 1: Measuring Sheet Metal Thickness With Tape. There are .Expanded metal panel is made of a single metal sheet and there are no welds or weak points, so it has sound structure. It can be treated by galvanized, PVC coated, powder coated, etc. With high corrosion resistance and various colors and patterns, it is widely used for fencing, decorating facade, interior design, guarding, screening, furniture . How do you measure sheet metal thickness? You can find the thickness of your sheet metal by using a measuring tape and a simple conversion technique. First, use the tape measure to find its thickness in millimeters. This helps get the most accurate measurement. Second, multiply the number of millimeters by 0.03937. gauge non-ferrous metal alum, brass, etc. inches galvanized steel inches standard steel inches stainless steel inches; 1.2893.2812: 2.2576.2656: 3.2294.2391.2500

Gauge numbers inversely correlate with sheet metal thickness: as the gauge number increases, the metal thickness decreases. For instance, 8-gauge sheet metal is substantially thicker than 16-gauge. . The concept of “gauge” as a thickness measure emerged during the American Industrial Revolution, driven by wire manufacturers’ need to .

typical automotive sheet metal thickness

Haze Meter convenience store

Resultado da 8 de jul. de 2022 · Beat the Beast: Griffin\'s Gold by Thunderkick Free Play ⚡ Full review of this 5 reels & 9 lines slot ⚡ Including Big Win Video and where to play for real money. . Beat the Beast: Griffin's Gold is a slot with 5 reels and 3 rows. You have 9 paylines, which bring you prizes. Some .

how do you measure the thickness of sheet metal|10 gauge sheet metal thickness